The Industry 4.0: manufacturing will become part of the information industry

The Industry 4.0: manufacturing will become part of the information industry

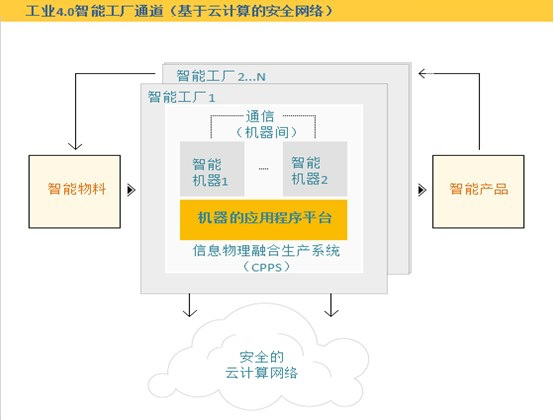

(Summary description)Starting last year, Germany, a manufacturing powerhouse, launched a national strategy called “Industry 4.0” that has attracted worldwide attention. It wants to apply Internet technology at every stage of the Industry 4.0, visualising the links between digital information and the real world and integrating production processes and management processes. From this, intelligent products are produced.

- Categories:2014 Year

- Author:

- Origin:

- Time of issue:2014-07-30 09:12

- Views:0

Starting last year, Germany, a manufacturing powerhouse, launched a national strategy called “Industry 4.0” that has attracted worldwide attention. It wants to apply Internet technology at every stage of the Industry 4.0, visualising the links between digital information and the real world and integrating production processes and management processes. From this, intelligent products are produced.

Question 1: Why 4.0?

Let us first review the main features of the previous industrial revolutions.

1.0: the First Industrial Revolution that began in Britain in the late 18th century and ended in the mid-19th century. As a result of this industrial revolution, mechanical production has replaced manual labor, and the Economic Society has changed from an agricultural and handicraft-based model to one in which industry and mechanical manufacturing drive economic development.

2.0: the Second Industrial Revolution took place in the early 20th century, when production lines were formed. Through the successful separation of parts production and product assembly, a new mode of product batch production is created.

3.0: since the 1970s, production has been optimized as electronic engineering and information technology have been enriched into industrial processes. The Digital Revolution begins with the Second Industrial Revolution process, which is highly automated. Since then, machinery has been able to gradually replace human operations.

4.0: over the next 10 years, Industry 4.0 will use network technology to determine manufacturing processes and automate them in real time.

From this we can see that the difference between 3.0 and 4.0 is not significant, relative to the difference between 1.0 and 2.0, or between 2.0 and 3.0. Yet the German Industry 4.0 report has definitions and explanations. But, in my view, Industry 4.0 is nothing more than “Factory intelligence”.

Just like today's smartphones, it has a variety of uses for taking photos, videos, networking and other applications. Similarly, Industry 4.0 include CRM (customer relationship management) , PDM (production data management) , SCM (industry chain management) , PLM (product life cycle management) , CAD (computer-aided design) and other systems as well as data processing, thus will be scattered all kinds of information summary analysis, for the new generation of manufacturing process to bring a decisive impact.

Q2: what exactly can Industry 4.0 achieve?

Specifically, in the Industry 4.0 era, management systems such as CRM, PDM, SCM and so on are likely to be merged in a smart factory. That way, the moment a customer orders something, the factory automatically sources the raw material from the supplier. After the raw material arrives, it will be given the data, “This is the raw material in the process of producing such-and-such products for such-and-such customers”, so that“Raw material” with information. Raw materials with information also mean having their own purpose or destination. If, in the production process, when the raw materials are mistakenly distributed to other production lines, it will be through the production equipment“Dialogue”, return to their own right production line; if, as production machines run out of raw materials, so too can they“Negotiate” with the order system to increase the amount of raw materials; eventually, even after the raw materials are embedded in the product, since it also holds path process information, it will be easy to trace the source.

In addition, the Industry 4.0 era is likely to bring more advanced features... For example: equipment can be self-discipline awareness maintenance period, management of the production status of remote monitoring, operation and management, resource allocation optimization...

Q3: How Should Industry 4.0 be evaluated?

Germany pioneered the concept of Industry 4.0, not least because it is a manufacturing power. As a manufacturing power, Germany has always wanted to maintain its leading position in global manufacturing. So Industry 4.0 is understood by many as a revival of traditional German manufacturing. But there is a sense that the Industry 4.0 is not just a recovery in manufacturing, but also a resurgence in information technology.

I think there is a key Industry 4.0. That is, the raw material purchased in the factory is given the message“This is the raw material in the process of producing a product for a customer”. In fact, it is not accurate to say that the raw materials are“Endowed” with information, but rather that the intelligent factory has used the“Raw materials” containing information. In the Industry 4.0 era, “Raw materials”= “Information”.

Conclusion: manufacturing industry will become a part of information industry

We usually call the industrial age the age of atoms and the information age the age of bits. The industrial revolution changed the atomic structure of the world with power, while the Information revolution changed the world's bit structure with computers and the Internet, and reconstructed a new information space. Atoms represent matter, bits represent information. In the age of bits, we can see that books in the media industry are transitioning from“Atomic” to“Bit”. But instead of eliminating atoms, the age of bits treated atoms as information (bits) . For example, after purchasing raw materials from suppliers, process information is added, distributed to the manufacturing plant, products are labeled at the time they leave the factory, and traceability is achieved during after-sales service. This process will be the whole process of production and manufacturing information management, the manufacturing process itself is always processing information. So Industry 4.0, rather, eliminates the distinction between “Information” and “Raw materials”.

Of course, some experts believe that Industry 4.0 can optimize production processes, reduce the amount of raw materials used, optimize the industrial chain, reduce environmental loads, reduce factory costs, and achieve high investment efficiency. ... But I think the biggest change in Industry 4.0 is that “Raw materials”= “Information”, and manufacturing and information industries will become synonymous. That is, from this point of view, manufacturing will eventually be part of the information industry.

Latest News

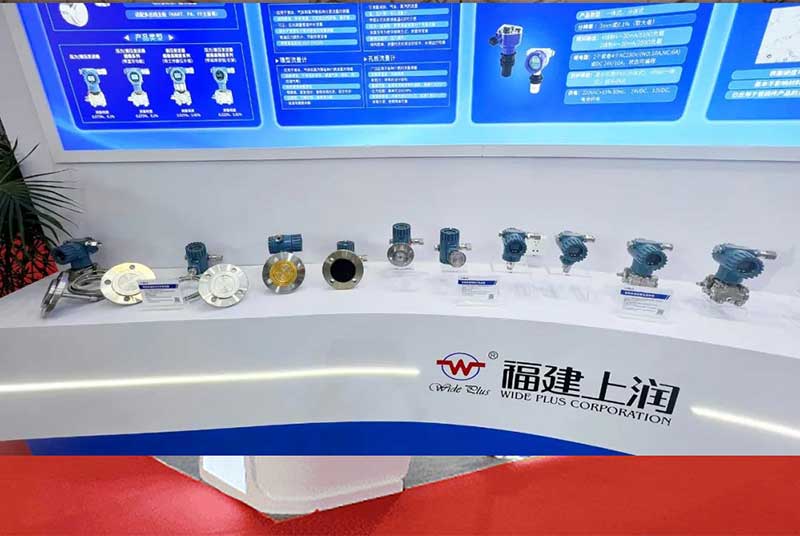

Wide Plus | Fujian Wide Plus multi-series products and systems appeared in Chengdu multi-national instrument exhibition

Fujian Wide Plus would like to invite you to the 32nd China International Exhibition on Measurement Control and Instrumentation

Former Hong Kong Chief Executive Carrie Lam and her delegation visited WIDE PLUS for research and guidance

The main business of Fujian WIDE PLUS Precision Instrument Co., Ltd. involves the R&D and manufacturing of pressure, flow, temperature, liquid level, photoelectricity, water quality and other parameter sensors as well as instrumentation tubes and valves in the industrial field; the R&D and manufacturing of high-precision automation equipments; high-precision mechanical machining; and the products and overall solutions of the city's intelligent water affairs.

Fujian WIDE PLUS Precision Instrument Co., Ltd.

ADD:No.16, Xingye West Road, Mawei High-tech Zone,Fuzhou,Fujian China

Email:

Toll-free technical service number:

400-887-6339

Follow Us On

Copyright © 2023 Fujian WIDE PLUS Precision Instrument Co., Ltd.

京ICP证000000号 Powered by saa